Our machines test luminous, electric, mechanical, geometric and functional properties of individual customer products. We also offer laser marking and labeling in 1D / 2D code, subsequently we read the code and add it to the database, where it is assigned to product data, so traceability can be ensured.

See examples of our applications.

Head Lamp Testing Machines

The machine is testing the luminous, electric, geometric and functional properties of final Head Lamp before packaging. Machine can have integrated laser for marking. If 1D / 2D code is on the product, the code is read and saved in database to part’s measured data and so traceability is ensured.

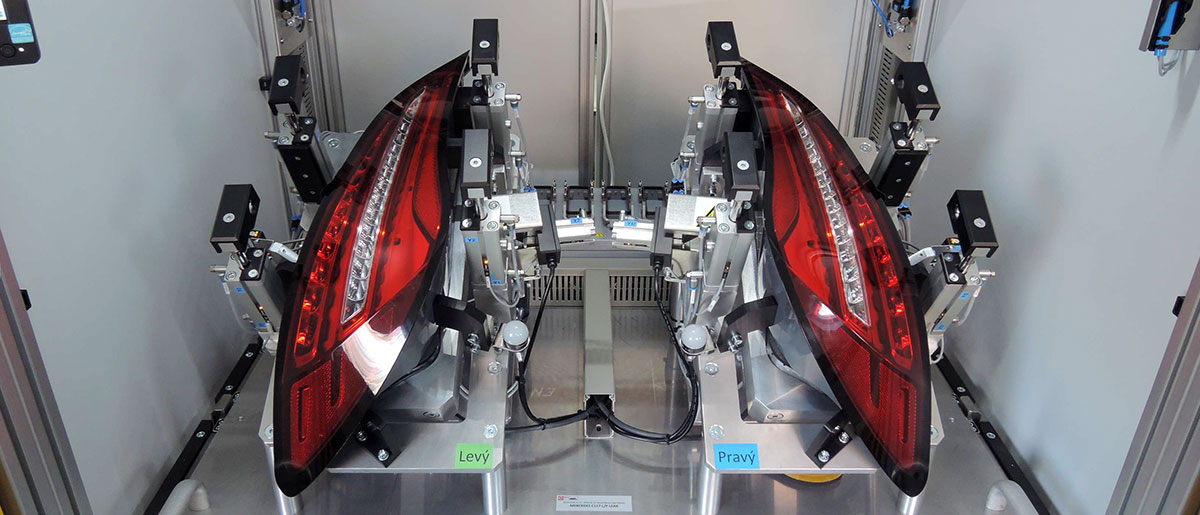

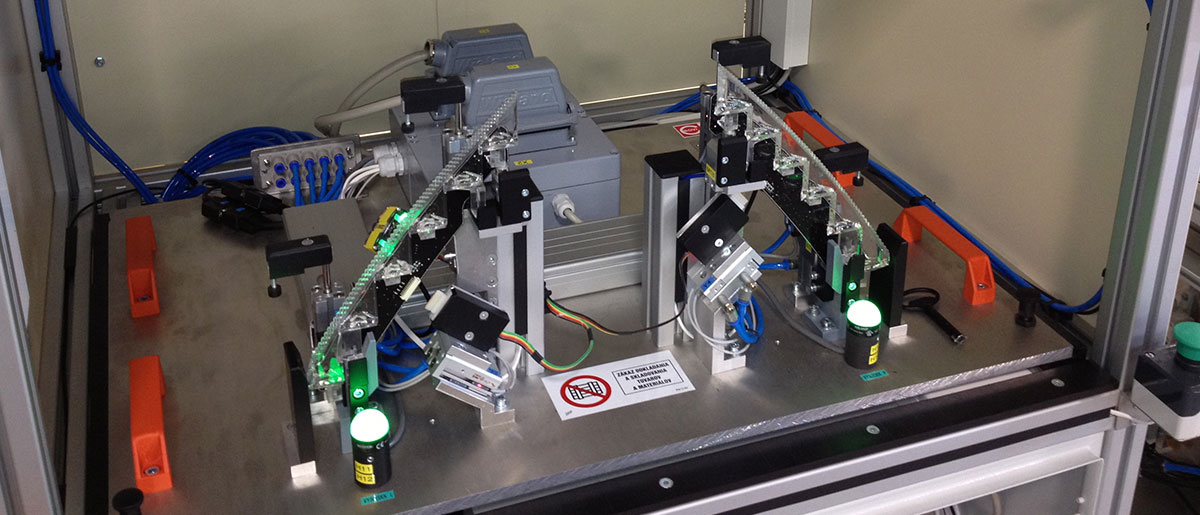

Rear Lamp Testing Machines

The machine is testing the electric and luminous properties of rear lamps. Each function of the lamp is checked. If requested, it is possible to e.g. apply a sealing or perform a leakage test. The machine may also contain a bar code reader for the traceability of the process. The machine contains a PC, which is collecting data, calculates statistics and saves all measured data in a database, so traceability is ensured.

Machines for Testing Day-Running-Light Modules

The machine is inspecting the electric-luminous properties, each LED is controlled in accordance with the set tolerances. The device may contain a bar code scanner for the traceability of the process. The machine contains a PC, which is collecting data, calculates statistics and saves all measured data in a database, so traceability is ensured.

Our customers are listed below

See our solutions in medical industry